Principais materiais

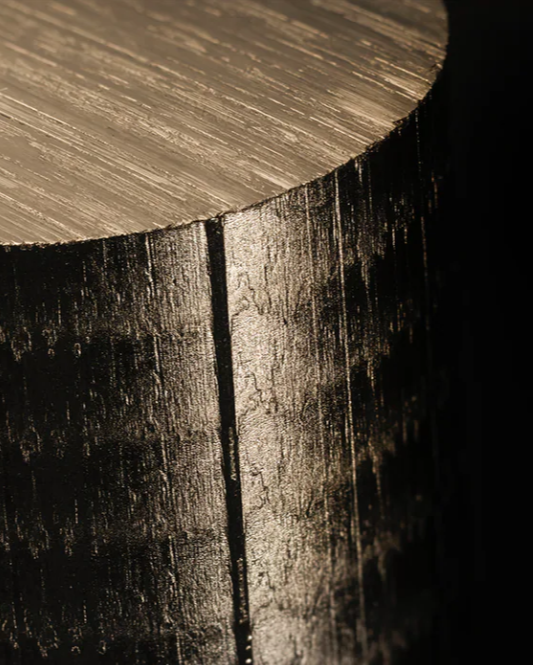

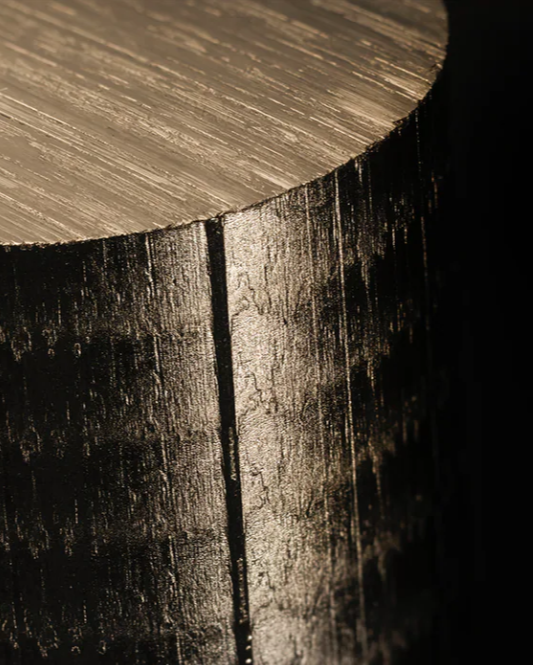

Titanium alloys are lightweight, corrosion-resistant, biochemically inert, and can withstand extreme temperatures. These properties make them particularly suitable for medical products, aircraft, and spacecraft. They strike a perfect balance between strength, corrosion resistance, and ease of work. Grade 2 titanium offers a soft gray color and is best suited for pieces with a "brushed" finish. It has been used in several OMEGA watches used for sports and space exploration, where light reflections must be avoided.

Titanium alloys are lightweight, corrosion-resistant, biochemically inert, and can withstand extreme temperatures. These properties make them particularly suitable for medical products, aircraft, and spacecraft. They strike a perfect balance between strength, corrosion resistance, and ease of workability. Grade 5 titanium offers a deep gray color close to that of stainless steel and is suitable for both brushed and polished finishes.

OMEGA created the exclusive Moonshine™ Gold, an 18K yellow gold alloy, in 2019. Inspired by the glow of moonlight on a dark blue sky, OMEGA's 18K Moonshine™ Gold offers a distinctive lighter hue than traditional 18K yellow gold and a high resistance to fading of color and luster over time. Its unique composition includes silver, copper, and palladium for color and stability.

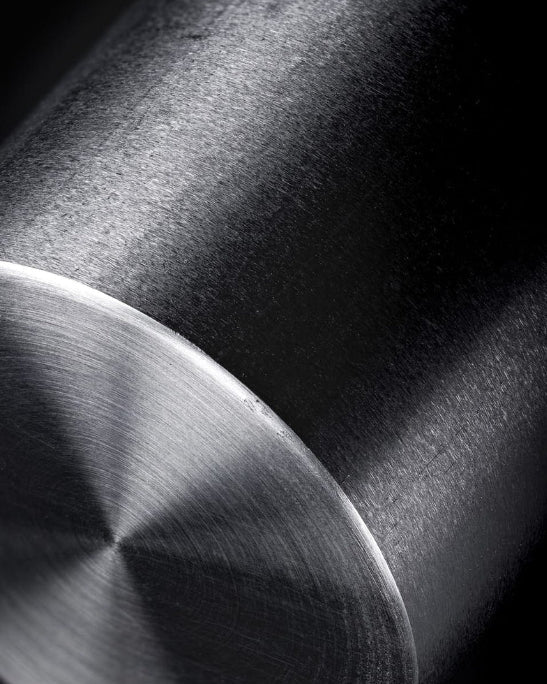

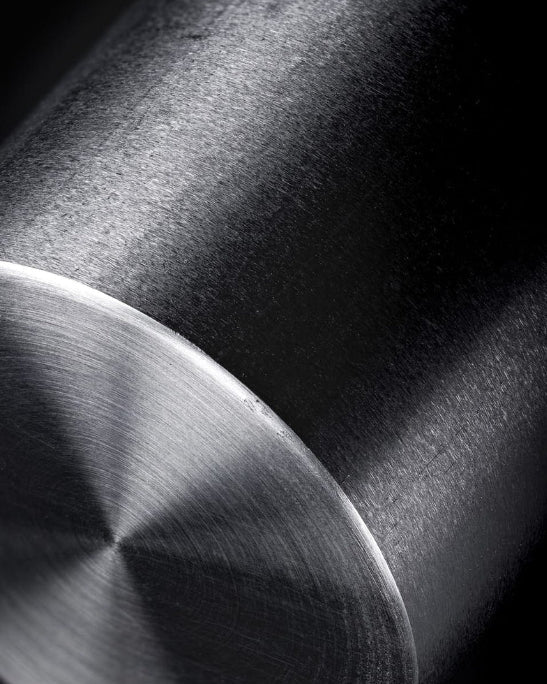

Stainless steel is certainly the most conventional watchmaking material for exteriors, offering beauty, strength, and value for money. OMEGA uses 316L stainless steel. Known for its corrosion resistance and high luster after polishing, this material is often the ideal choice for both everyday watches and those designed for highly demanding situations, such as diving and adventure watches.

OMEGA has unparalleled expertise in the use of ceramics, which began over 10 years ago. Originating from the Greek word "keramos," ceramic is an inorganic, non-metallic substance obtained by firing at high temperatures. It allows for the creation of fully dense watch parts with exceptional mechanical properties. Ceramic is one of the most popular choices for customers when selecting their watch, thanks to its appealing range of colors and specific properties, such as being twice as light as stainless steel, robust, highly scratch-resistant, chemically inert, hypoallergenic, environmentally friendly, and non-magnetic.

To truly appreciate every detail of a watch, OMEGA uses synthetic sapphire crystal with a highly scratch-resistant and anti-reflective coating. Before machining and finishing, sapphire crystals are produced using the Verneuil process, also called flame fusion. This involves melting the raw material using an oxygen/hydrogen flame and crystallizing the molten droplets to form a cylinder. With a grade 9 on the Mohs hardness scale (graded 1-10), the resulting sapphire crystals are virtually scratch-resistant and very hard, ensuring that vision is never impaired.

OMEGA created the exclusive Moonshine™ Gold, an 18K yellow gold alloy, in 2019. Inspired by the glow of moonlight on a dark blue sky, OMEGA's 18K Moonshine™ Gold offers a distinctive lighter hue than traditional 18K yellow gold and a high resistance to fading of color and luster over time. Its unique composition includes silver, copper, and palladium for color and stability.

Stainless steel is certainly the most conventional watchmaking material for exteriors, offering beauty, strength, and value for money. OMEGA uses 316L stainless steel. Known for its corrosion resistance and high luster after polishing, this material is often the ideal choice for both everyday watches and those designed for highly demanding situations, such as diving and adventure watches.

OMEGA has unparalleled expertise in the use of ceramics, which began over 10 years ago. Originating from the Greek word "keramos," ceramic is an inorganic, non-metallic substance obtained by firing at high temperatures. It allows for the creation of fully dense watch parts with exceptional mechanical properties. Ceramic is one of the most popular choices for customers when selecting their watch, thanks to its appealing range of colors and specific properties, such as being twice as light as stainless steel, robust, highly scratch-resistant, chemically inert, hypoallergenic, environmentally friendly, and non-magnetic.

To truly appreciate every detail of a watch, OMEGA uses synthetic sapphire crystal with a highly scratch-resistant and anti-reflective coating. Before machining and finishing, sapphire crystals are produced using the Verneuil process, also called flame fusion. This involves melting the raw material using an oxygen/hydrogen flame and crystallizing the molten droplets to form a cylinder. With a grade 9 on the Mohs hardness scale (graded 1-10), the resulting sapphire crystals are virtually scratch-resistant and very hard, ensuring that vision is never impaired.