Secure checkout powered by Shopify Payments and PayPal

AUTUMN SALE 2025 - UP TO 50% OFF

We are currently offering our last batch with a 50% discount. These products may never be available at this price again.

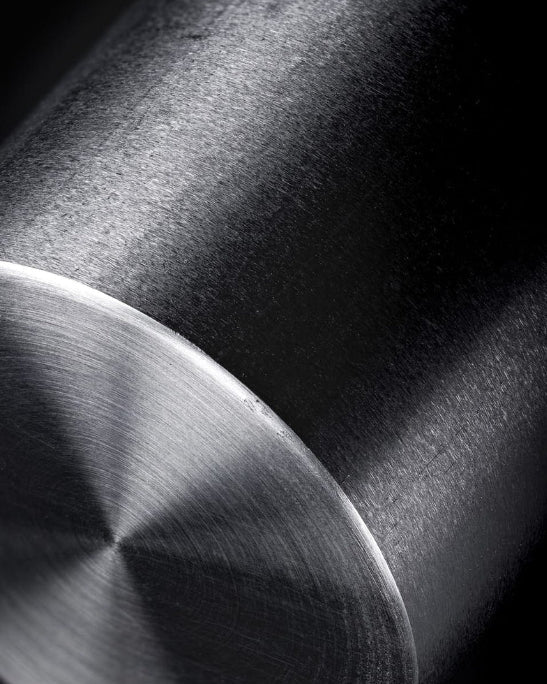

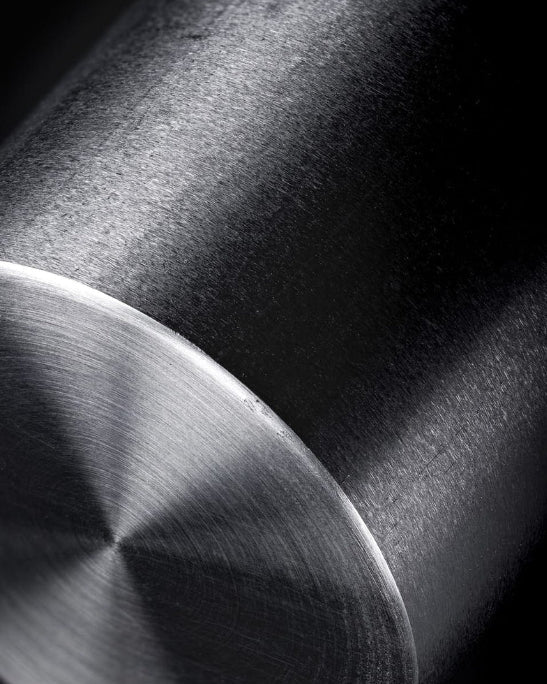

Material – Stainless steel (polished & brushed)

Diameter – 43.0 mm

Thickness – ~14.1–14.2 mm

Lug-to-lug – ~49–50 mm

Lug width – 21 mm

Water resistance – 150 m (15 bar)

Crystal – Domed sapphire, AR both sides

Caseback – Sapphire exhibition

Type – Co-Axial Master Chronometer (automatic)

Power reserve – ~60 hours

Anti-magnetic – Resistant to 15,000 gauss (METAS)

Functions – World time, date, hours/minutes/seconds

Frequency – 25,200 vph

Material – Structured blue rubber (Summer Blue tone)

Integration – Polished steel centre link at lugs

Width – 21 mm at lugs

Clasp – Steel deployant (folding)

Compatibility – Fits 21 mm lug width (Aqua Terra 43 mm case)

Finish – Gradient Summer Blue with vertical “teak” pattern

World map – Laser-ablated relief globe at center

24-hour ring – Glass ring with light/dark blue day–night scale

Cities ring – Coordinated Summer Blue palette

Hands / Indexes – Rhodium-plated, luminous (Super-LumiNova®)

Main materials

To truly appreciate every detail of a watch, OMEGA uses synthetic sapphire crystal with a highly scratch-resistant and anti-reflective coating. Before machining and finishing, sapphire crystals are produced using the Verneuil process, also called flame fusion. This involves melting the raw material using an oxygen/hydrogen flame and crystallizing the molten droplets to form a cylinder. With a grade 9 on the Mohs hardness scale (graded 1-10), the resulting sapphire crystals are virtually scratch-resistant and very hard, ensuring that vision is never impaired.

Stainless steel is certainly the most conventional watchmaking material for exteriors, offering beauty, strength, and value for money. OMEGA uses 316L stainless steel. Known for its corrosion resistance and high luster after polishing, this material is often the ideal choice for both everyday watches and those designed for highly demanding situations, such as diving and adventure watches.

To truly appreciate every detail of a watch, OMEGA uses synthetic sapphire crystal with a highly scratch-resistant and anti-reflective coating. Before machining and finishing, sapphire crystals are produced using the Verneuil process, also called flame fusion. This involves melting the raw material using an oxygen/hydrogen flame and crystallizing the molten droplets to form a cylinder. With a grade 9 on the Mohs hardness scale (graded 1-10), the resulting sapphire crystals are virtually scratch-resistant and very hard, ensuring that vision is never impaired.

Stainless steel is certainly the most conventional watchmaking material for exteriors, offering beauty, strength, and value for money. OMEGA uses 316L stainless steel. Known for its corrosion resistance and high luster after polishing, this material is often the ideal choice for both everyday watches and those designed for highly demanding situations, such as diving and adventure watches.

The advantages of this watch

Inside this watch are revolutionary components that guarantee the highest standards of performance. From the Co-Axial escapement for lasting precision to the silicon balance spring for superior antimagnetism, OMEGA has conquered every challenge that matters.

Inside this watch are revolutionary components that ensure the highest standards of performance. From the Co-Axial escapement for lasting precision, to the silicon balance spring for superior anti-magnetism, OMEGA has conquered every challenge that matters.

Twice as Precise as Any Officially Certified Chronometer

Our Master Chronometer watches are tested and certified twice. First, the movement is certified as a Chronometer under the ISO3159 standard by the Contrôle Officiel Suisse des Chronomètres (COSC). Then, the fully cased watch undergoes eight Master Chronometer tests set by the Swiss Federal Institute of Metrology (METAS), requiring precision of 0/+5 seconds per day.

Patented Antimagnetic Materials

Everyday objects such as mobile phones, magnetic clasps, laptops, MRI equipment, induction hobs or automatic doors expose watches to magnetic fields, which can disrupt their performance. To avoid permanent deviations of several minutes per day, we use antimagnetic materials like the silicon balance spring, capable of withstanding the strongest fields.

To guarantee integrity at depth, every OMEGA watch – not just some – is fully immersed in water and pressure-tested up to the guaranteed water resistance. By testing every watch, we go far beyond the usual industry standards.

In our pursuit to raise industry standards and push the limits of quality, all OMEGA watches are delivered with a full 5-year warranty. This commitment reflects the confidence we have in our timepieces, offering customers extra peace of mind.

Expect fewer visits to the service center. The Co-Axial escapement was designed to reduce mechanical limitations inside the movement, requiring less lubrication and therefore less servicing. Compared to non-Co-Axial watches, service intervals are significantly longer.

During certification, OMEGA watches undergo extreme testing, including shocks to ensure reliability and accuracy even after heavy impacts. Each watch is designed to resist shocks equivalent to a 1-meter fall onto solid wood, generating forces up to 5000G for a 150g watch.

Superior Precision

Antimagnetic

Water Resistance

5-Year Warranty

Less Servicing

Shock Resistance

Movement

Self-winding movement with Co-Axial escapement. Master Chronometer certified and METAS approved, it is resistant to magnetic fields up to 15,000 gauss. GMT/Worldtimer functions. Free-sprung balance with silicon balance spring; automatic winding in both directions. Rhodium finish with Geneva waves in arabesque.